Newsletter Q3 2024

Our car from last season, the LR24. A still sleeping beauty. We will use this Newsletter as a quarterly update, to share new things from our team and our next race car. If you want more frequent updates make sure to follow us over on Instagram.

We’re entering the exciting concept phase for the new season. With boundless enthusiasm and determination, we’re pursuing our primary goal: building a fully functional race car. This crucial phase lays the foundation for our next racing LR car. As in previous years, we’re harnessing cutting-edge technologies. Our race car will be electrically powered and feature autonomous driving capabilities. By combining electric mobility and autonomous driving, we’re tackling the most pressing challenges in motorsport. We’re confident that our concept will not only yield a race-ready car but also lead us to success in the upcoming competitions.

Organisation & Marketing

Marketing Initiatives and Future Vision

The newly established Marketing Team has hit the ground running, demonstrating impressive initiative and creativity right from the start. We have an extensive array of strategic plans in development, all aimed at elevating our team’s profile and impact. Looking ahead to the 2025 Season, our primary objective is to significantly increase awareness of our team, both within the University community and throughout our hometown of Braunschweig. We’re not stopping there, though. We’re also committed to collaborating with our regional partners to elevate the status of Formula Student, aiming to make it a more widely recognized and respected competition. While we acknowledge the magnitude of this challenge, our entire team is united in this vision and driven by an unwavering determination to see it through to fruition.

Recruiting Efforts and Achievements

Our recent recruitment drive has been remarkably successful, bringing in over 30 potential new team members. These individuals come from a diverse academic background, representing more than 5 faculties and 10 different areas of study. This influx of fresh talent and perspectives is particularly beneficial for our Electronics department, which has received a significant boost in human resources. It’s worth noting that our team’s growth doesn’t stop here; we anticipate welcoming even more first-semester students during the winter months, further enriching our team’s composition and capabilities.

Organizational Achievements and Future Goals

Reflecting on our past performance, we’re proud to report that our team demonstrated exceptional prowess in all quizzes during the previous year. Building on this success, we’ve set ambitious goals for the upcoming season. Our primary objective is to secure a coveted spot in the prestigious Formula Student Germany (FSG) competition. Additionally, we’re aiming to participate in at least one other high-profile event. To achieve these goals, we’ve already initiated a comprehensive planning process. Our team is working diligently behind the scenes, meticulously preparing every aspect of our strategy to ensure we’re fully prepared when the time comes to showcase our skills and innovations on the international stage.

Suspension & Powertrain

Due to a recent internal restructuring, our department has undergone significant changes. The VD & Performance team has transferred the Performance segment to our ASS colleagues, while we have now integrated the Powertrain function with all its mechanical components from the former Power and Electronics department.

Our newly formed department, Suspension and Powertrain, is designed to reflect its scope of responsibility. The Suspension Group oversees the development and optimization of critical mechanical components such as wheel carriers, pedal boxes, steering systems, control arms, brake systems, and brackets. Meanwhile, the Powertrain Group is responsible for the development of the vehicle’s drivetrain systems, including rims, motors, cooling systems, wheel hubs, gearboxes, and tires.

We are currently optimizing the wheel carrier based on lessons learned from the LR24 model, with a key focus on reducing weight while maintaining structural integrity. In parallel, the pedal box is being redesigned to endure higher loads, ensuring reliability under competitive conditions. The positioning of the control arms is being optimized to reduce unwanted forces, which can negatively impact the vehicle’s kinematic performance. Similarly, the brackets are undergoing refinement, aiming to minimize weight while improving ease of installation and modularity to facilitate future adjustments.

Within the Powertrain Group, one of our engineers is conducting a master’s thesis on carbon fiber (CFK) rims. This innovation aims to significantly reduce the overall weight of the car, contributing to improved lap times and vehicle handling.

Another exciting project is focused on all-wheel-drive kinematics and the integration of 10-inch tires. One of our engineers is working on this as part of their master’s thesis. While our immediate goal is to perfect the rear-wheel-drive configuration, once that is achieved, we aim to build upon that foundation to incorporate all-wheel-drive systems for future vehicles. This phased approach ensures that we maintain a solid baseline of performance before exploring more complex drivetrain configurations.

As we continue to work on these projects, our primary focus is on fine-tuning and optimizing existing components from the LR24 to push the boundaries of performance for the LR25 and onwards.

In summary, our efforts are centered on creating a robust, reliable, and high-performing vehicle for the upcoming season. The combination of optimized systems and cutting-edge materials positions us well for competitive success, and we’re confident that our ongoing improvements will deliver tangible results on the track.

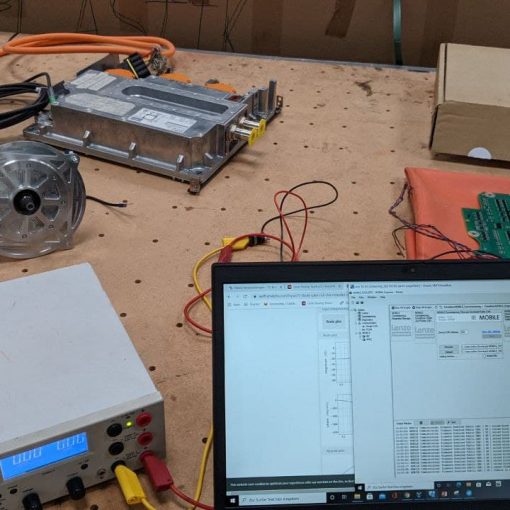

Electronics

The Electronics department is responsible for designing and manufacturing the car’s high voltage and low voltage systems. The high voltage system runs at the maximum allowed voltage of 600V and consists of the battery, inverters, motors, and wiring. Our new accumulator is a ground-up redesign, retaining only the same pouch cells as the old one, given our experience with them and their prior purchase. For the first time, we plan to compress the cells to enhance their performance and longevity. Beyond this, our main concept for the accumulator is to „KISS“ (Keep It Simple, Stupid), aiming to produce the simplest and most reliable accumulator possible. This approach is crucial as the accumulator is vital for driving the car at full power, and fine-tuning the car and drivers takes precedence over marginal weight savings. We’ve opted for a metal container over composite sandwich containers. While the latter save weight, they’re more time-intensive, costly, and difficult to manufacture. They also consume precious space due to thicker walls. Given that our accumulator must fit in the rear opening of our monocoque—approximately 175mm high—every millimeter saved is significant. Compared to the old container, we’ll reduce weight by using a welded structure with thinner metal walls than the floor and thinner sheets overall. The low voltage system, powered by a DC/DC converter inside the accumulator, supplies 24V to all other electrical components in the car. This system will undergo a complete overhaul this season, implementing new concepts like a backplane and a dual bus system. The backplane, a housing located behind the seat, contains nearly all of the vehicle’s circuit boards. This centralization allows for easy function checks and servicing. Each PCB features LEDs to indicate errors or malfunctions, making issues immediately visible upon seat removal. Previously, car communication relied on CAN bus, but bandwidth limitations forced us to use several separate buses. Our new car will employ CAN FD, allowing all car data to be shared on a single CAN bus thanks to increased bandwidth. This upgrade enables more comprehensive diagnostic data, simplifying troubleshooting. Additionally, we’ll implement a second, parallel bus for full redundancy, ensuring the car can continue operating if one bus fails. In past seasons, the Electronics department was chronically understaffed. Consequently, we’re prioritizing the completion of parts required for legal manual driving, receiving substantial support from other departments. We’ve also appointed an organizational department leader to alleviate the workload of our more technically skilled members. Thanks to major recruiting efforts, we’ve welcomed eight new department members this semester, most of whom are well-advanced in their studies. Despite the extensive work involved in redesigning much of the electrical system, the outlook is finally improving for both the department and the team as a whole.

Aerodynamics & Chassis

Our department combines two distinct groups. The chassis team develops and manufactures our carbon fiber monocoque, along with all essential crash protection, rollover hoop, driver ergonomics, and various mountings and housings throughout the car. As the monocoque forms the central part of our racecar, our work is crucial not only for driver safety but also for ensuring all other components fit properly and function as intended. The aerodynamics team, on the other hand, designs and manufactures all wings and aerodynamic devices, while simulating airflow around the vehicle using CFD software. Although not strictly necessary for driving, the aerodynamics package generates significant downforce, pressing the car into the ground. This increases our cornering speed and greatly impacts overall track performance. Both groups are united by our use of fiber-reinforced composite materials, which increase part strength while keeping the car’s overall weight low. For instance, our monocoque weighs only about 25kg without cutouts—less than 10% of the car’s total weight, despite its size. This year, our department will build upon the solid foundation we created last year. As we’ll reuse the LR24’s monocoque, the chassis team will focus on improving other crucial components. We’re developing a container for the new accumulator to protect and secure the stacks and electronics. We’re also redesigning the rear lid, which closes the monocoque cutout for accumulator insertion and secures it to the chassis. We aim to significantly reduce weight in both areas, making the car lighter overall and shifting the center of gravity slightly forward. For our aerodynamic package, we’re making minor adjustments and optimizing airflow to maximize our main wings‘ effectiveness. We’re modifying the front wing’s upper flaps to improve rear flow management, particularly focusing on increasing outwash. This will push dirty air and turbulence from the front tires away from the car, reducing interference with airflow underneath the car—where most downforce is generated. Simultaneously, we’re adjusting the sidepods to increase airflow beneath the wing while maintaining adequate flow to our cooling radiators, compared to our current open-front design. By optimizing clean airflow around our wings, we can increase downforce and enhance overall performance.

Autonomous System & Simulation

At the end of the 2024 season, we restructured our team for management and technical reasons. We created two new departments from the former Performance and Driverless departments: the Autonomous System department and the Simulation department. The Autonomous System department combines all software and hardware aspects working directly inside the car without active driver inputs. This includes the former Performance department’s tasks like Traction Control System (TCS) and Torque Vectoring, as well as the driverless functionality. The Simulation department focuses solely on simulation. This restructuring reduces interfaces between departments and simplifies the creation of a combined concept. For our driverless system, we’re developing a simple concept using Python/C++ and ROS2. Our goal is to create an easy-to-understand base for future generations, as this might be our first season of actual driverless implementation. We plan to use a twin camera setup with LIDAR as our car’s „eyes.“ For cone detection, we’ll use an optimized YOLO v10 neural network for camera images and Euclidean clustering for LIDAR point clouds. We’ll then combine and map this data to calculate a simple midline trajectory through the track’s cones. Vehicle State Estimation (VSE) using GPS, acceleration, and other sensors will help determine the car’s position. All necessary software, including TCS and Torque Vectoring, will run on a single centralized computer to improve simplicity and reduce interface work. While this Autonomous System is still in its concept phase, we’re working closely with the rest of the team to refine it. We’re simultaneously developing integration details and software concepts. We’re also building a mini test car to trial our system without straining resources from other departments. The young Simulation department is focusing on two main tasks: 1. Creating a simple Laptime Simulation to easily check the influence of different car parameters. 2. Developing a sophisticated simulation using CarMaker for virtual driving and software testing. We’re currently setting up the Laptime Simulation framework and parameterizing the CarMaker model with real-life car data. This work is ongoing, as we continuously strive to improve our models and simulations for better results.